Reuse versus recycling

However, this success also fosters a status quo that could prove difficult to change when society and industries want to progress further towards circular economic models .

The purpose of recycling organizations is to recycle as much as possible. On the surface, this appears to be a welcome objective, but it might work in opposition to the next best step in the circular economy: reuse before recycle. If reuse was increased substantially, it could mean a drop in recycling, which might threaten the economic sustainability of some recycling organizations.

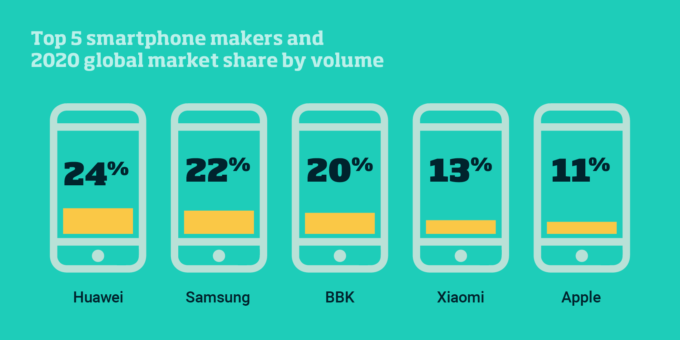

Take phone makers. The 88% waste rate for materials and minerals suggests that the phone industry is primarily a linear economy and beyond the reach of recycling. But pressure from regulators and consumers to act is growing. This is where reuse could make a substantial difference. In fact, many argue that reusing is a better option to start the journey with than recycling.

The problem is that reusing often requires a new business model and a full company and ecosystem transformation – but it can be done.

For example, an equipment manufacturer started to move to reuse around eight years ago and realized that it needed to switch from selling equipment to a pay-per-use model. Pay per use created the appropriate business model for the manufacturer to recover equipment, refurbish it, send it back to the customer and to design the equipment for reusability. This evolution has triggered the development of new competencies such as managing the state and life cycle of different components for reuse and to change them only when needed.

It is crucial to understand that this kind of business model transformation has many implications for the economic sustainability of a company. In many aspects, it is similar to software companies moving from selling software to the software-as-a-service (SaaS) model. It changes cash flow generation: Rather than a one-off upfront payment, it creates a stream of recurring payments over time. As a consequence, the equipment becomes the property of the vendor and it should be financed by the vendor. Thus, the finance model changes substantially.

It also creates a need to transform the way customers buy, with knock-on implications for the way clients’ purchasing departments work. They are no longer buying a product but a service or solution.

Thankfully, digitalization is now making this kind of transformation viable. Through the Internet of Things and industry 4.0, for example, the vendor can monitor the state of equipment remotely. And, finally, it requires a new level of trust between the supplier and the customer and a joint development plan to work further on reusability and the circular economy.

Imagine the ideal future and make it happen

While this level of transformation might seem complex and formidable, it is important to remember that most successes in this field have taken many years to develop and achieve and, like most transformations, required a constant stream of trial and error to learn and build a better model.

The dilemma is that, if we start in an incremental way by focusing and investing solely on recycling first, we might create future disincentives for the addition and adoption of reuse.

So, we cannot work incrementally.

Instead, we should create a vision of how our whole industry might function in 10 years by maximizing the potential for a mix of reuse, reduction and recycling. Based on that vision, we should work backwards to develop the evolutionary steps that will lead the company towards it. This the path that long term successes in the circular economy are following.

To move to a future in which we can reuse the materials in our PCs, laptops, mobile phones and tablets, companies need to imagine that future and commit to a concrete plan to get there, while convincing clients and consumers that reuse is a better option and managing each transformation proactively.

Audio available

Audio available